Understanding ceramics together

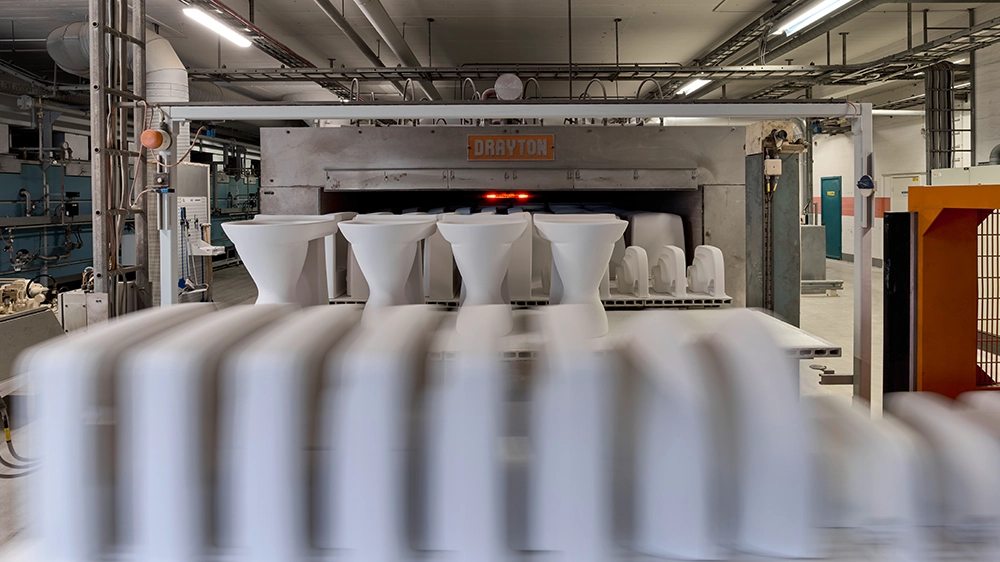

Office and production employees gain an in-depth insight into the production of ceramic appliances at the in-house academy at the Bromölla (SE) plant.

Head of Department Joachim Lindberg and his some 20-strong team are responsible for ceramics technology at the plant in Bromölla. He has been at the company for around 25 years and has seen the plant change from a traditional factory into a modern casting hub.

Joachim, what is the aim of the academy?

Course participants should understand how the ceramic process works from A to Z. This goes beyond their own area of responsibility. It improves mutual understanding of the individual process steps. By exchanging ideas, we understand what we can do together to further improve quality. Of course, it’s also about passing on knowledge internally.

What is a training course like?

It is a mixture of theory in the meeting room and practice in the production plant. We go through the process step by step, from the raw material to slip production, drying, glazing and firing through to the finished product. We also look at each process directly in the plant and discuss the respective challenges.

Training is aimed at office and production staff. An interesting mix.

Indeed, training is an exciting time. Right at the beginning, I let everyone know that there is no such thing as a stupid question. The participants took this to heart and weren’t shy about asking questions. This led to some interesting discussions. After all, production staff look differently at the process compared to their colleagues in design. Getting them around a table in relaxed surroundings was very valuable.