Sheet metal parts for the entire world

Many Geberit plants need components made of sheet metal for their products. The Geberit Huter plant in Matrei in Tyrol (AT) takes care of production of these parts for the entire Group.

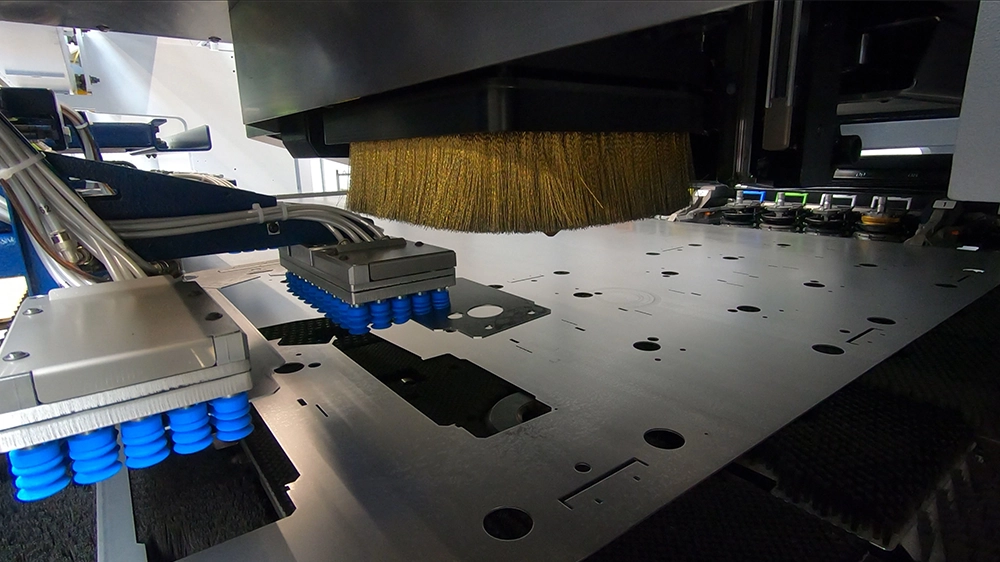

Brackets, fastenings, casings: sheet metal plays an important role in manufacturing many Geberit products. Until now, purchasing agents at the Geberit plants had to procure these parts from external suppliers. Thanks to a new laser punching machine at the Geberit Huter plant in Matrei (AT), this is no longer necessary.

Twenty punches per second

“Laser punching is a new technology at the Geberit Group,” says Markus Peer from the production engineering team in Matrei. The sheet metal parts are often manufactured in small batches and with complex designs, which results in a wide portfolio of parts across the entire Group. It is planned that the system will soon run in three-shift operation – without the need for staff during the night. It can process sheet metal parts with a thickness of up to 8 mm using punching or laser cutting. The machine consists of over 100 cutting tools, with the tool changeover taking place without any interruptions in the production process. Up to 20 punches per second can be carried out. The laser cuts precise contours with burr-free edges.

Laser punching is a new technology at the Geberit Group.

More efficiency, less waste

Bends, tabs, counterbores, threads and lettering are then easy to produce. What’s more, different parts can be made from a single sheet, which minimises waste. Head of Department Harald Greier is a happy man: “I was hoping and waiting for this machine for many years. It is now a great new challenge and motivation for me and my team to work with it.”