On the high seas

Geberit products can be used in various ways in shipbuilding. The market is growing in Türkiye in particular.

The factory buildings at the ADA Yacht Works in Bodrum are a hive of activity. Two yachts measuring 50 metres are currently being built here. Each yacht takes two years to build and costs around 22 million euros. Managing Director Onur Tekin says: “The market is booming.” This is also being felt by Geberit in Türkiye. The shipbuilding business has seen significant growth since the pandemic.

CuNiFe for salt water

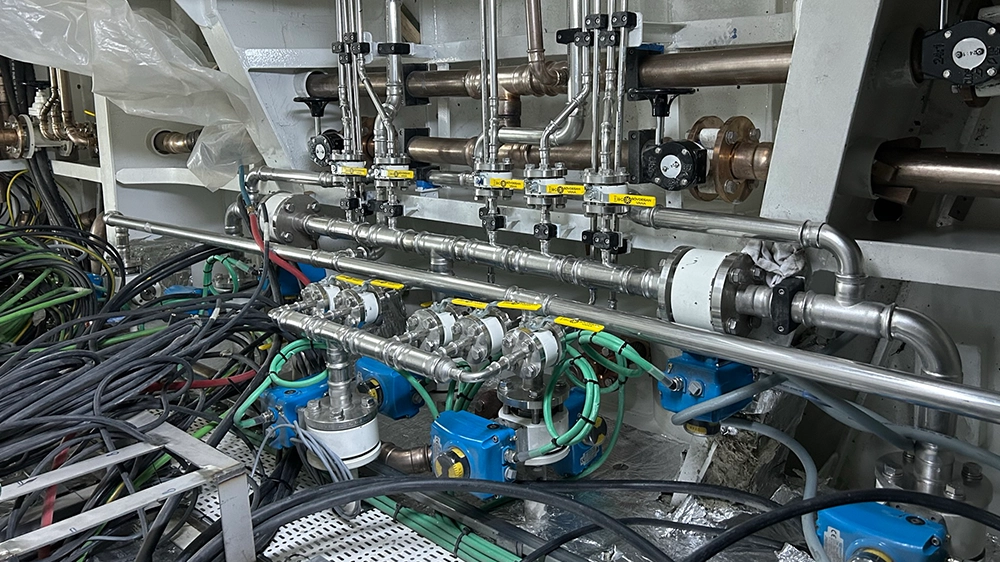

At Geberit, shipbuilding is closely associated with Mapress CuNiFe, a supply system made of an alloy of copper (Cu), nickel (Ni) and iron (Fe). The corrosion-resistant system is ideally suited to applications in salt water.

However, shipbuilding also uses other Geberit products such as Mapress Stainless Steel for fuel lines or PE pipes for drainage applications. Onur Tekin is a huge fan of Geberit shower drains. In rough seas, conventional traps empty – which leads to unpleasant odours. “In the S-shaped traps from Geberit, the water seal remains intact.”

With Mapress, we are six times faster than with a welded system.

Efficient processing increasingly important

Quality is paramount in the luxury shipbuilding segment. According to experts in the branch, Türkiye has caught up with other European markets here. However, it is becoming harder to find personnel to keep up with increasing orders. This means that efficient processing is even more important. “With Mapress, we are six times faster than with a welded system,” says Onur Tekin. “This really pays off.”