All about the flow

The new piping system has been met with an extremely positive response in the industry, and demand for it is high. This poses some challenges for the production plant in Rapperswil-Jona (CH).

FlowFit

Geberit FlowFit is a piping system for drinking water that sets new standards in terms of user-friendly and reliable installation. In this way, FlowFit ensures quick and easy installation. The optimised geometry of the fittings also improves water flow.

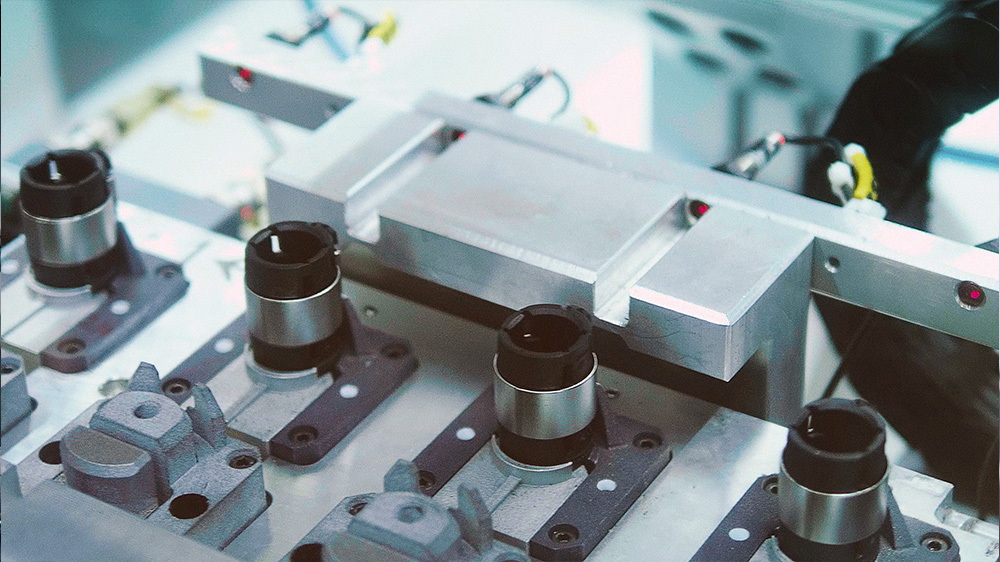

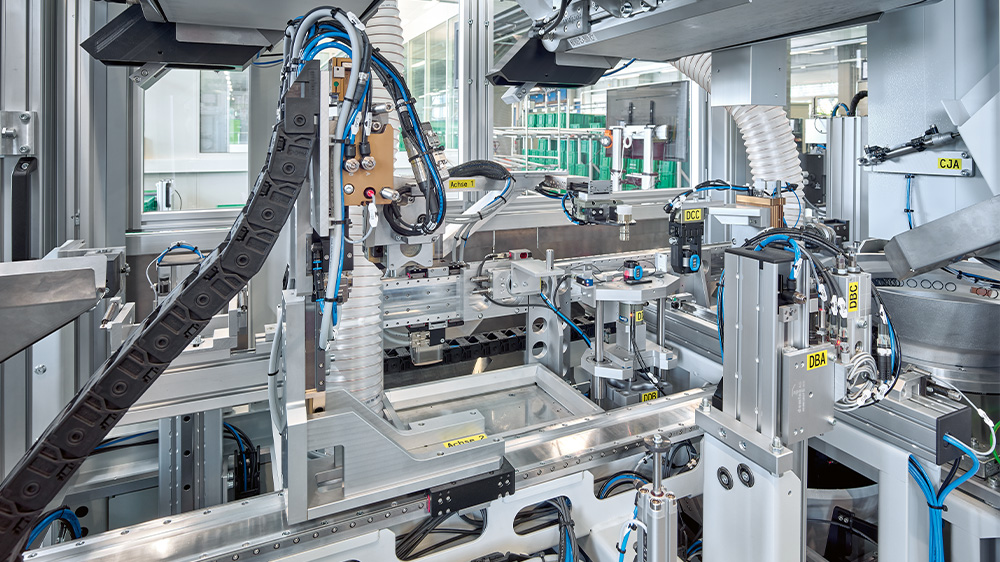

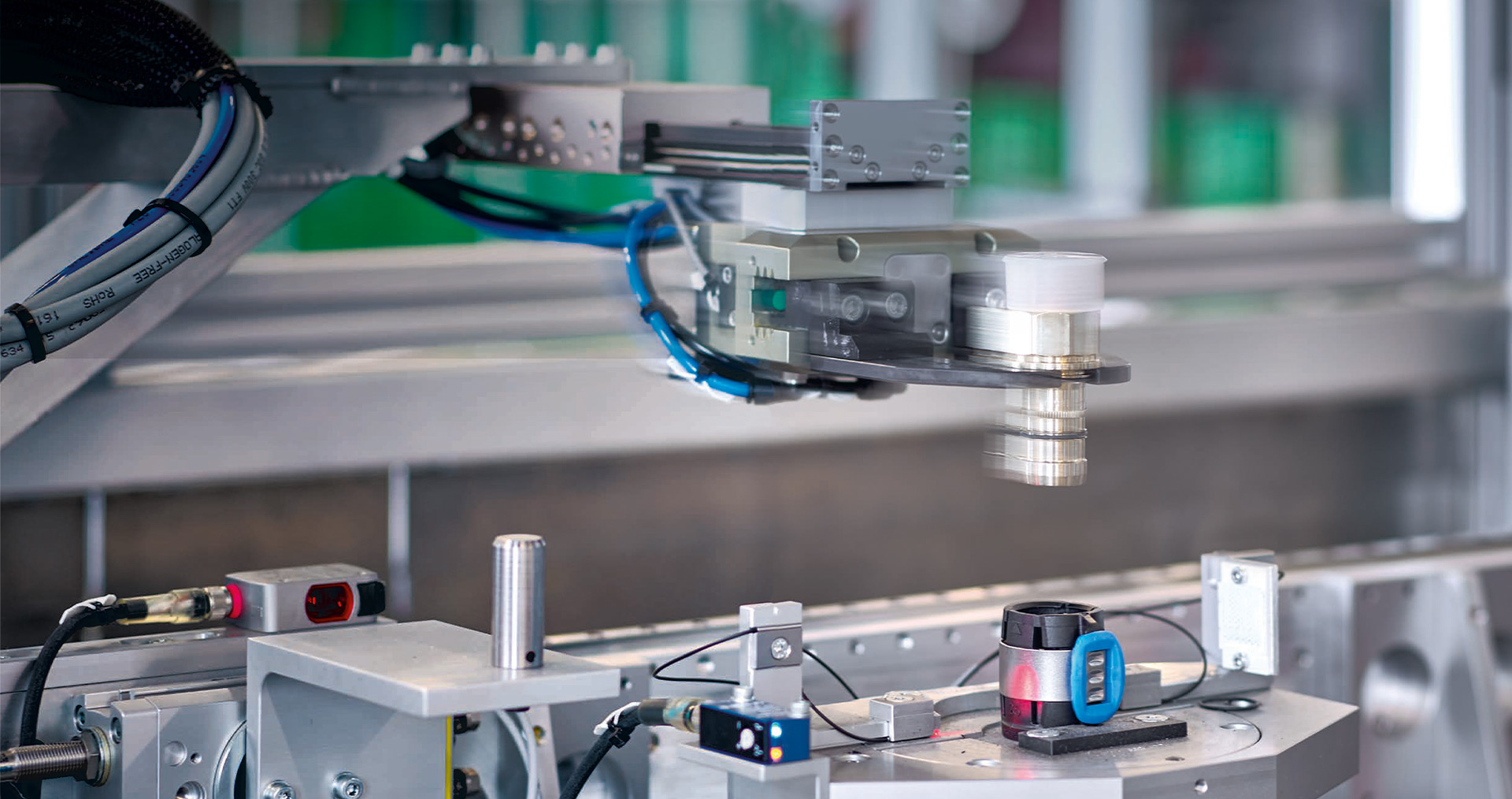

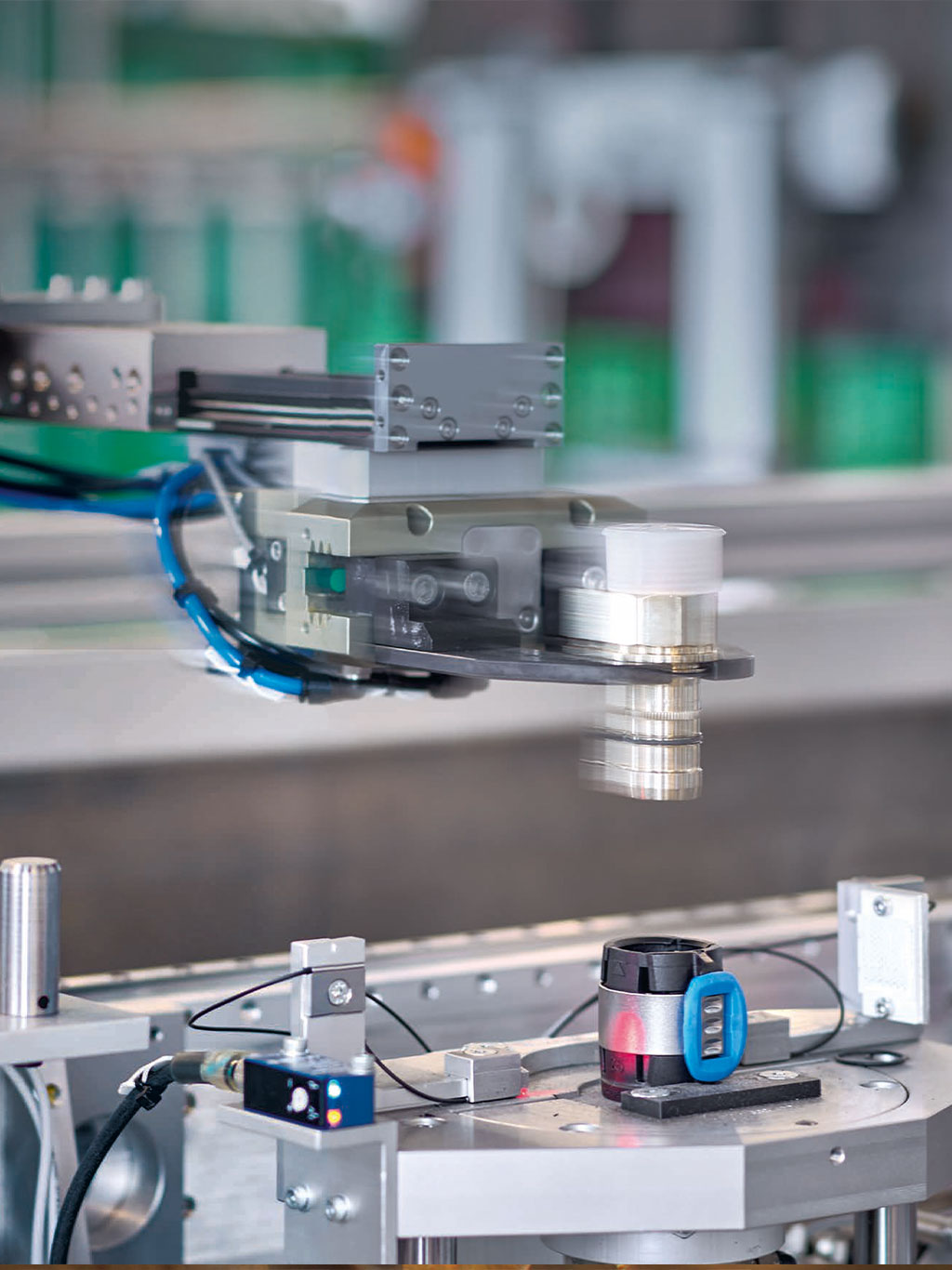

The machinery used in FlowFit production is impressive: eight injection moulding, assembly and packaging lines, 23 assembly modules, three injection moulding machines for accessories, two press body assembly systems and two assembly lines for metal fittings are in constant operation at Geberit headquarters in Switzerland. The production and assembly of the several hundred components seen in the FlowFit range have to be synchronised perfectly with each other and in the correct sequence. Manufacturing takes place in fully automated production cells. The modular assembly lines are mounted on rollers, meaning they can be moved easily. “This speeds up the set-up process to other fitting dimensions enormously,” comments Hubert Britschgi, Head of Supply Chain Management at the production company in Rapperswil-Jona. The system is then ready for production of other FlowFit fitting parts within a matter of minutes.

High demand

Even long before market launch in April 2021, the production lines were running virtually around the clock. “We produced a generous amount of stock in advance thanks to four-shift operation lasting several months, and were thus prepared for high levels of demand,” comments Hubert Britschgi. However, the demand ended up being so high that stock levels were exhausted in next to no time. Geberit FlowFit is now available in eight countries and regions. As the supply system will be launched in further markets in the future, an expansion of production in Rapperswil-Jona is already being planned.